INS8321B

Mini ITX form factor, Intel® Cedarview D2550 CPU on board, Extended Temperature. -40°C to 85°C

- Intel® Cedarview D2550 CPU + Intel® NM10

- Single/Dual channel 18/24-bit LVDS

- Rich I/O interface with 10 COM, 7 USB, 2 LAN

- Flexible expansion with 1 x mPCIe

- 16bit DIO (8 in/8 out)

- 9 ~24V wide voltage DC-in design

- Extended operating temperature. -40°C to 85°C

- Technical Profile

- Specifications

- CPU

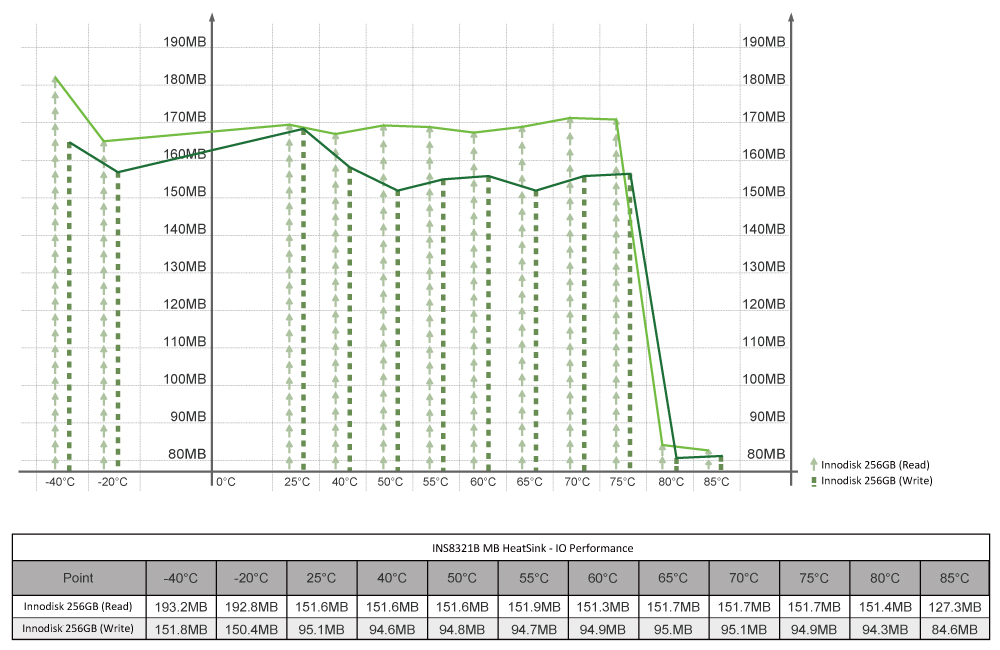

- SSD Performance

- Thermal Solution

- Introduction

-

INS8321B is a Mini-ITX form factor industrial motherboard, designed with Intel® Cedarview D2550 CPU soldered onboard. Processor D2550 supports dual core 1.86 GHz, presenting only 10W extremely low power consumption with high performance. With processor soldered onboard can significantly enhance the resistance of vibration and shock. Extensive I/O interface with 10 COM ports and 16 bit DIO can increase a variety of possibility for device connect ability. Extended temperature operation from -40 to +85°C ensures unbeatable reliability and wide range DC-in 9 ~24V design can protect the board from damages caused by sudden surge of voltage. INS8321B is rugged SBC and expected to be a good solution for automation and transportation industry.

- Thermal solution for fanless system– the incorporation of two pure copper heat pipes and aluminum heat sink

-

Thermal design is the solution for the maximum reduction of heat. With upper passive aluminum heat sink and cooled aluminum enclosure is implemented to create an effective dissipation environment. With two pure high efficiency copper heat pipes plus aluminum heat sink to ensure maximum thermal efficiency. Copper vacuum Heat-Pipe has effective thermal conductivities that range from 5,000 W/m•K to 200,000 W/m•K to effectively transfer heat from the heat source to the heat sink. This advanced thermal solution enables system to operate smoothly under temperature range -40 to 80°C -without processor throttling.

- Effective cooling solution for maximum heat dissipation

-

Perfectron implements unique cooling solution with the copper heat spreader and aluminum heat sink. To adopt the physical property of copper and aluminum, the copper heat spreader touches the heat source - processor and chipset and absorbs the heat rapidly, heat is then transferred to upper aluminum heat sink; the aluminum heat sink dissipates the heat into surrounding air promptly. The heat sink design with high and low shape to create temperature difference then produce airflow, the wave lines on the lateral side of heat sink can increase the dissipating interface up to 30 to 40%. Through above unique design could achieve maximum heat dissipation.

- Installation Instruction

-

Procedure:

Stick thermal pad on CPU and chipset, and then place passive heat sink on thermal pad.

1.Thermal Pad

Thermal pad is aid the conduction of heat away from the component being cooled (such as CPU or chip) and into the heat sink.- The unit of Heat Transfer Coefficient for thermal pad is W/m.K. The higher the Heat Transfer Coefficient number is, the better thermal conductivity for thermal pad could reach. PERFECTRON adopts thermal pad with 17 W/m.K which is military standard level that can guarantee the maximum thermal conductivity between components and heat sink

2.Aluminum Passive Heat Sink

Heat sink is known for lowering the temperature by dissipating heat into the surrounding air. PERFECTRON implements aluminum heat sink instead of copper because aluminum can dissipate the heat more rapidly than copper due to metal characteristic- It contains 96 % of aluminum, 127 mm length, 48 mm height, and weighs 315 g

- Consume shorter heat dissipating time owing to lower metal density

- Better performance in heat dissipating

Operating Temp.

Can withstand extended temperature from -40 to 85°C

|

Operating Temp. |

|

|---|---|

|

UT : -40°C to 85°C |

|

|

System |

|

|

CPU Type |

Intel® Atom™ D2550 1.86GHz onboard |

|

Chipset |

Intel® NM10 Express Chipset (Intel® CG82NM10 PCH) |

|

Memory Type |

2 x 204-pin SO-DIMM DDR3 800/1066 MHz up to 4GB |

|

BIOS |

AMI® BIOS |

|

Super I/O |

IT8786E |

|

Watchdog |

1-255 sec. or 1-255 min. software programmable, can generate system reset |

|

Expansion Slot |

|

|

PCI slot |

1 x 32bit support 33MHz |

|

mSATA |

1 x SSD storage compatible with PCIe Mini Card |

|

Mini PCIe |

1 for GEN2 |

|

Display |

|

|

Chipset |

Intel® PowerVR SGX545 Graphic core |

|

Onboard VGA |

Yes (Max. resolution 1920 x 1200 @ 60 Hz) |

|

LVDS |

Support 18/24-bits LVDS single/dual/channel DP: 2560 x 1600 @ 60 Hz eDP: 1920 x 1080 @ 60 Hz |

|

Onboard DVI-D |

Yes (Max. resolution 1920 x 1200 @ 60 Hz) |

|

Dual Independent Display Capability |

VGA+DVI, VGA+LVDS, LVDS+DVI |

|

Audio |

|

|

Codec |

Realtek ALC887 |

|

Ethernet |

|

|

Chipset |

2 x Intel® 82574L GbE LAN (support 10/100/1000 Mbps) |

|

Disable LAN through BIOS |

Yes |

|

WOL |

Yes |

|

Boot from LAN |

Yes for PXE |

|

Rear I/O |

|

|

VGA |

1 x 15-pin VGA connector (female) |

|

DVI-D |

1 x 25-pin DVI-D connector (female) |

|

Audio |

Line-out, Mic-in |

|

Ethernet |

2 x RJ45 |

|

COM |

1 x RS232/422/485 with 5V/12V selection (COM1) 1 x RS232 with 5V/12V selection (COM2) |

|

|

Serial Signals RS232: DCD-, RXD, TXD, DTR-, GND, DSR-, RTS-, CTS- RS422: TX-, RX+, TX+, RX-, GND, RS485: DATA-, DATA+, GND |

|

USB |

4 ports with 5V |

|

I/O Interface |

|

|

SATA |

2 x SATAII (3 Gb/s) |

|

USB |

3 ports by pin header |

|

COM |

8 x COM ports COM3~COM10 ports support RS232 with 5V/12V selectable by pin header (COM5 port supports RS232/422/485 with 5V/12V selectable) |

|

PS/2 |

2 x 4-pin header |

|

LVDS |

2 x 15-pin connector |

|

Fan |

CPU/System fan connectors |

|

Parallel Port |

2 x 13-pin header |

|

DIO |

pin header (for cash drawer) |

|

OS support list |

|

|

Windows |

Windows 7 x32、Windows 7 x64 |

|

Linux |

Fedora 10、Fedora 14、Open SUSE 12.2、Debian 7.0.0 |

|

Mechanical and Environment |

|

|

Form Factor |

Mini-ITX Industrial MB |

|

Power Type |

9V to 24V DC-in |

|

Dimension |

170 x 170 mm (6.7" x 6.7" ) |

|

Operating Temp. |

UT : -40°C to 85°C |

|

Storage Temp. |

-40°C to 85°C |

|

Relative Humidity |

10% to 90%, non-condensing |

|

Certification |

|

|

Vibration test |

IEC 60068-2-64 Random Vibration test Frequency: 5Hz to 500Hz Acceleration: 3.0 g rms Test Axis: X, Y, Z axis Test Time: 30Min (Each axis) |

|

Shock test |

IEC 60068-2-27 Shock test Wave form: Half Sine Wave Acceleration: 100g Duration Time: 6ms |

|

MIL-STD-810G |

Temperature Shock: MIL-STD-810G Test Method 503.5 Temperature Shock Procedure I-C / Storage (Multi-cycle shocks from constant extreme temperature, Form 85℃ to -40℃, Three cycle)

High Temperature: MIL-STD-810G Test Method 501.5 high Temp ( 96 hours @75℃ non-operating + 72 hours @ 75℃ operating )

Low Temperature: MIL-STD-810G Test Method 502.5 Low Temp ( 96 hours @ -40℃ non-operating +72 hours @ -40℃ operating ) |

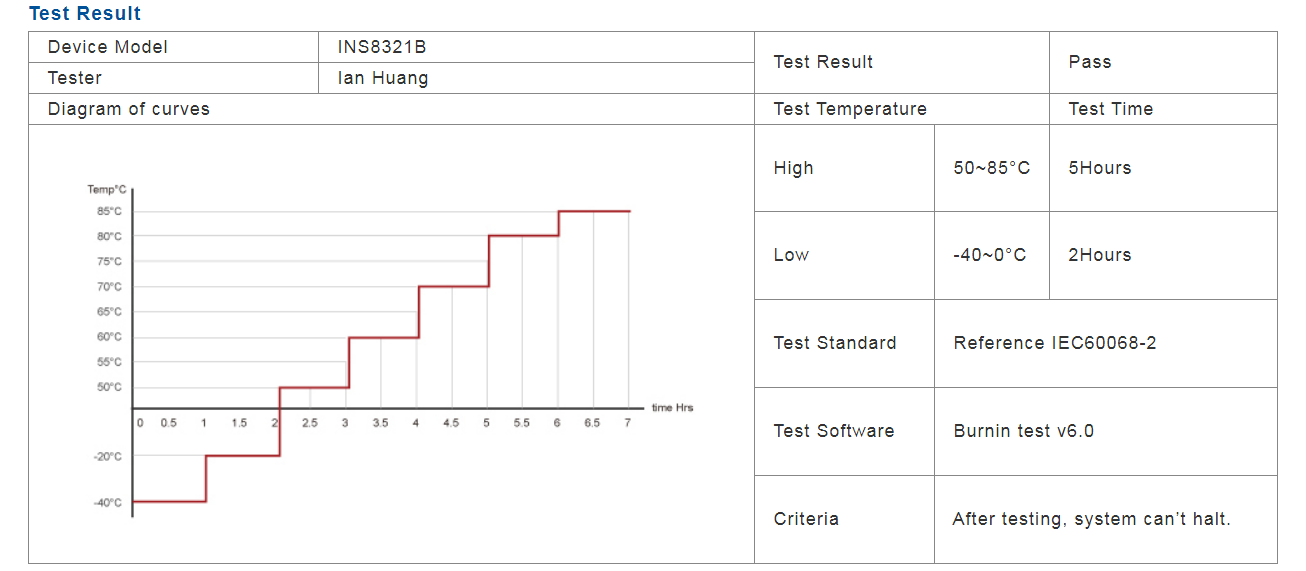

- Test Result

-

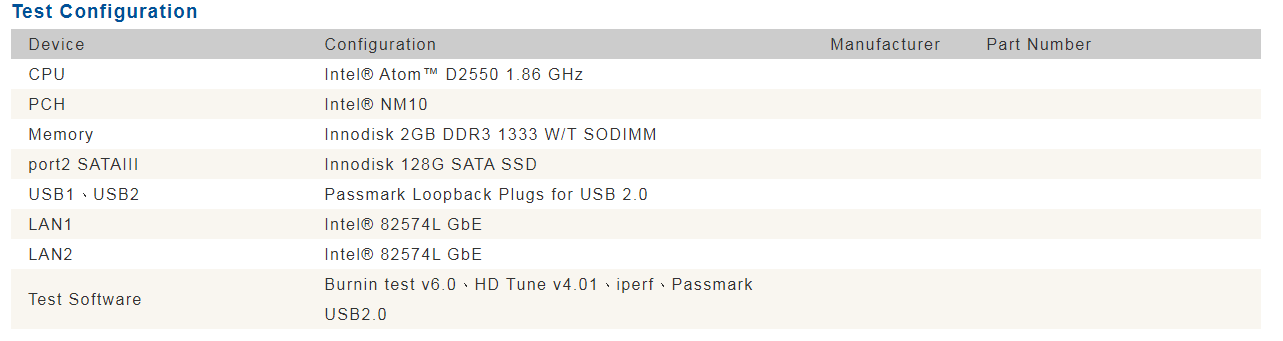

- Test Configuration

-

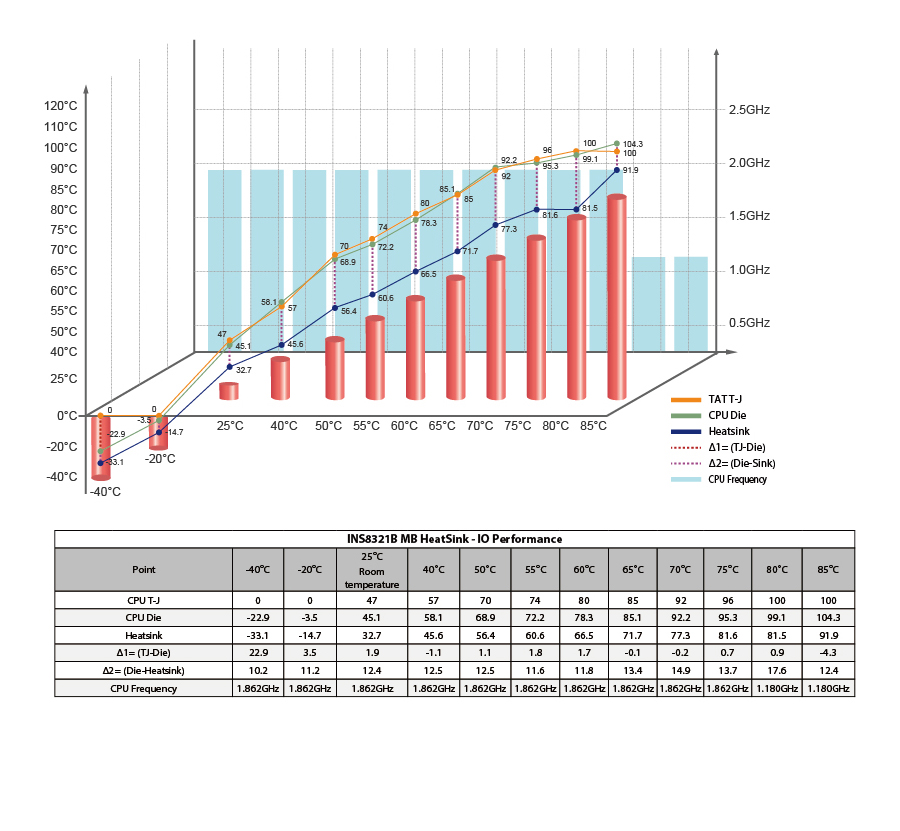

- Thermal Measurement

-

PERFECTRON provides real lab testing figures to show how CPU performance is with each tailor made thermal kits as important references and design guide for system engineers. For system integration, the crucial challenge is the operation performance under high temperature, thus PERFECTRON conducts long time experiments to make sure the superior testing result for all critical missions. By revealing temperature at processor T junction, processor die and heat sink, PERFECTRON is able to analyse the thermal solution we designed achieves maximum efficacy and observe CPU performance. The high temperature testing takes 5 hours which at each temperature point we burn in INS8321B for one hour, from +50 to +85°C.

- Related System — PER321A

-

PER321A is powered by Intel® Atom™ Cedar trail D2550 dual core processor soldering onboard which is a high-reliability Atom-based fanless rugged system. The system works perfectly under 70°C without processor throttling. PER321A features an abundance of connectors through its I/O interface; it supports two COM ports for RS232/422/485 and another four for RS232, two RJ45 Ethernet LAN ports, four USB 2.0 on rear I/O and two by pin header, plus two mPCIe or one mSATA, all impressive capabilities provided for saving R&D resource during system integration or application implementation. PER321A applied copper vacuum tube liquid-vapors and accompanied by the best ratio of heat dissipation volume in the industry, PER321A still operates smoothly with 1.86GHz clock rate speed under 70°C harsh environment. With its durability and anti-vibration resistance, it perfectly interprets a highly reliable solution for automatic optical inspection, industrial automation, access control, data acquisition, and digital signage.

- System main board: Mini-ITX SBC INS8321B

-

(1) Intel D2550 CPU soldering onboard

PER321A is based on Mini-ITX industrial motherboard, designed with D2550 processor soldering on board. With processor soldering on board can enhance the resistance of shock and vibration to allow product operates under every possible condition. With processor solder on board would lower resistance and inductance at the connection enhance effective transmission that could guarantee better and more high frequency performance for the system.

(2)High scalability and flexibility

PER321A is an industrial-grade system designed with high scalability and flexibility. Based on different necessity, COM ports can expand from six to ten that allow users to apply more specialized and custom-built devices. 16-bit DIO can meet a variety of industrial applications requirement which including the control of switches, relays, actuators, fans, lights, and motors that enable PER321A to achieve superior performance in industrial control and manufacturing test systems such as factory automation, embedded machine control, and production line verification.

(3)Wide Range DC input

For certain application such like transportation and military always challenge the risk of unstable power that might cause damage to the system. Wide range DC input becomes an indispensable element for those applications. PER321A support 9V~ 24V DC-in to protect system from damage caused by sudden surge or peak voltage. This feature guarantee the system increasing migration path flexible and eliminate redesign of existing power architecture

(4)Three-stage thermal design

Industrial application solutions usually demand to operate in extreme conditions such as high/low temperatures, thermal shock and high humidity. Thus the extended temperature solution becomes extremely significant. PERFECTRON implements three-stage thermal design for PER321A to allow system survive under temperature range -40 to +70°C . The three-stage thermal design is using aluminum heat spreader to absorb heat directly from heat sources, then use heat pipe to transfer heat to aluminum heat sink to surrounding air. The copper heat pipe is the key factor among the whole thermal design. The heat conductivity of heat pipe can reach up to 5000, which is 12 times better than copper heat spreader. With such advanced thermal solution enables PER321A to operate in a torrid environment without processor throttling.

- Supports Intel® Atom™ D2550 CPU

- 2X DDR3 SO-DIMM up to 4 GB

- 2X Mini PCIe slot (1X mSATA co-lay)

- Dual GbE LAN ports

- Support 1X 2.5”SATA HDD/SSD

- 6X COM ports

- 6X USB ports

- 9V~24V DC-in

- Supports extended temp. -40 to +70°C

- Advanced cooling solution for better heat dissipation

-

To meet the demands of customer’s extended temperature requirements, the whole thermal solution of INS8335C simultaneously embraces two heat transfer methods, heat conduction and heat convection. For heat conduction, the solution utilizes a copper heat spreader on the bottom layer which directly contact with the processor and chipset. Heat is then transferred to upper aluminum heat sink. Regarding to heat convection, the temperature differences caused by high and low fin design forms a mild airflow that could bring away heat efficiently. Fan can also be an auxiliary by placing an appropriate sized fan on top of the heat sink. Breakdown drawing is provided as below.

Thermal Pad

After countless experiments, PERFECTRON’s experienced engineer team has learned valuable lessons about the best thickness of thermal pad from failures.- Precision design of thermal pad: the gap between CPU die and heat sink should be less than 1mm.

Aluminum Heat Spreader

- 96 % purity of aluminum, 26 mm high and weigh 340 g

Pure Copper Heat Pipe

Heat pipe transfers heat from the heat sources to the heat sink over relatively long distance. Two-phase heat transfer involves the liquid-vapor phase change of a working fluid.- The longer ones are 365mm in length, 99.9% purity of copper.

- The shorter ones are 157mm in length, 99.9% purity of copper.

- High heat conductivity efficiency up to 5000.

Aluminum heat sink on dual side chassis

- 96 % of aluminum, 24 mm height and weighs 394 g