INS8335C

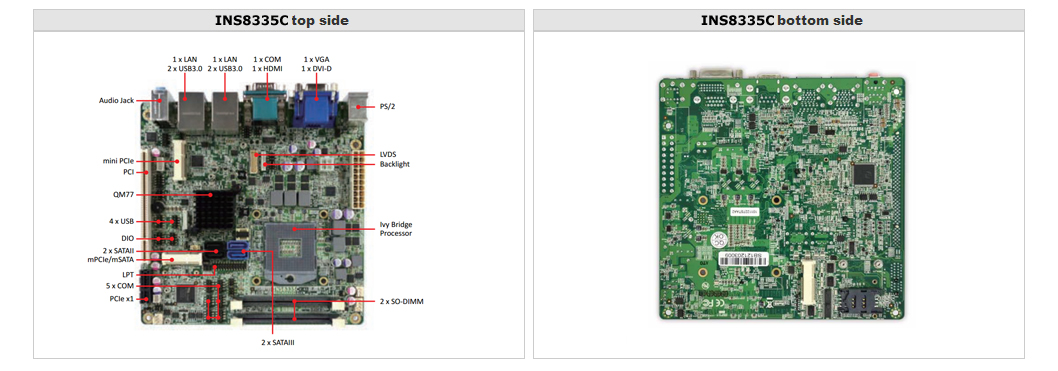

Intel® Ivy Bridge QM77 Mini-ITX Industrial MB, Wide Temp. -20°C to 70°C (-40°C to 85°C optional)

- Intel® 22nm Ivy Bridge Processor (Mobile)(rPGA988)

- 2 x DDR3 SO-DIMM up to 16 GB

- Muliti-display: VGA, DVI-D, LVDS, HDMI

- 1 x PCI, 1 x PCIe x1, 2 x Mini PCIe, 1 x mSATA

- 4 x SATA (2 x SATAIII, 2 x SATAII)

- 8 x USB ports (4 x USB 3.0, 4 x USB 2.0)

- 6 x COM ports

- 16-bit DIO (8 in/8 out)

- Wide operating temp. -20°C to 70°C (-40°C to 85°C optional)

Download

- Technical Profile

- Specifications

- CPU

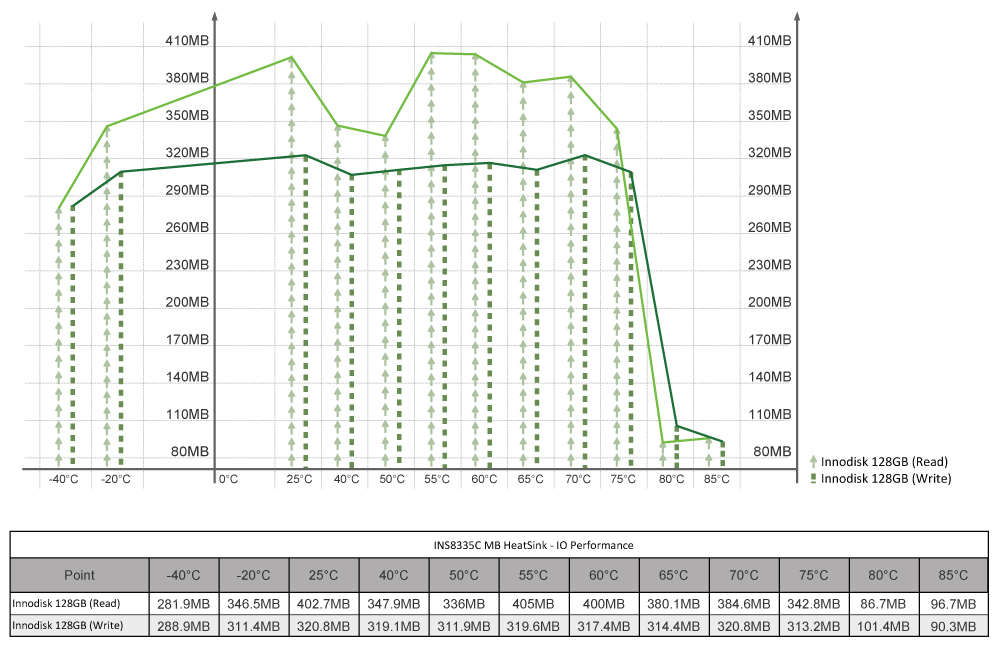

- SSD Performance

- Thermal Solution

- Introduction

-

INS8335C is a Mini-ITX form factor industrial motherboard, powered by Intel® Ivy Bridge 22nm processor and QM77 chipset. Processor i7-3610QE plus Intel® QM77 chipset consumes only 45W and 4.1W individually. It supports four-core that can turbo up to eight-core. CPU co Extreme computing power and reliability are guaranteed by this powerful combination. Clock speed can boost from 2.3 GHz to 3.3 GHz. ATX power supply unit provides two connectors for the motherboard: a 4-pin auxiliary connector providing additional power to the CPU and a main 24-pin power supply connector. Wide range 9V~24V DC input design can protect the board from damages caused by sudden surge of voltage, thus further secure the reliability. Extended temperature operation from -40 to +85°C ensures unbeatable reliability. Fast processor equips with rich legacy I/O features such as: 6 COM ports (3 by RS485/232/422); 16 Bit DIO; LPT; PS2. The expansion capacity of INS8335C is stunning, it supports 1 x PCI, 1 x PCI_e, 1 x mPCI_e, and 1 x mSATA. A set of PS/2 connectors is specially installed for convenient keyboard & mouse usage. With various extensive ability and strong computing power, INS8335C is a key solution for industrial automation such as drilling machines, drilling rigs, and CNC machine applications.

- Integrated thermal solution – the incorporation of four pure copper heat pipes and an copper heat sink

-

INS8335C, with its dynamic 4-core 45W core i7-3610QE processor, demands an equal high level thermal solution. To achieve maximum heat dissipation, the design and implementation of heat pipes is the golden key. In this case, a copper heat sink and passively cooled enclosure is implemented to establish an effective dissipation environment. The structure of four pure copper heat pipes is to ensure supreme thermal efficiency. The heat pipes are capable of prompt dissipation of the heat generated by the CPU’s inner core while it’s computing. According to Perfectron’s testing result, each pure copper heat pipe has the ability to dissipate 9w of heat. The combination of four heat pipes pushes the dissipation ability to a new level. Our tailor-made, precision-aimed integral structural heat sink and embedded heat pipes constitute an excellent fanless thermal solution. When the CPU hits 100% full potency, the implementation of four 6mm (minimum) pure copper heat pipes can keep it running at full speed – 2.3 Ghz!

- Effective cooling devices for maximum heat dissipation

-

Perfectron’s unique heat sink and heat pipe are designed with precision. Each of the key heat-dissipating components is tailor-made in accordance with different interior and exterior structure. Unlike traditional solutions that utilize aluminum as the dissipating media for CPU and fin. We insist on incorporating 99% pure copper heat spreader, which is eight times higher in density than aluminum. Our tailor-made pure copper heat spreader is treated with the most precise CNC technology, cutting four 6.1mm wide track so that the 6mm wide heat pipes can fit seamlessly. Compared with conventional solid heat conductors, such as aluminum, copper, granite, and graphite, of which thermal conductivity ranges from only 250 W/m•K to 1,500 W/m•K, Perfectorn’s effective heat pipe design, with impressively high thermal conductivity (5000 W/m•K to 200000 W/m•K) that is 40 times higher than standard aluminum, is guaranteed to charge the system to the maximum turbo speed with minimum overall impact.

- Installation Instruction

-

Procedure:

The thermal pad is first placed directly on top of the CPU die to create a tight connection between the two. The custom made heat spreader, with four semi-circle trails precisely CNC milled, houses the four pure copper heat pipes securely. The top layer is a flat aluminum heat sink that can achieve the most effective heat dissipation solution.

1.Thermal Pad

Thermal pad is widely used to aid the conduction of heat away from the component that needs to be cooled down (e.g. CPU) and into the heat sink.- To determine the effectiveness of a thermal pad, the unit “K” is applied. Most of the other companies in the embedded market employ materials under K10 for economic reason. Perfectron, with the target of reaching CPU full speed without throttling, incorporates only K17 military grade as our principle specification.

- The thinner the thermal pad is the better effect it creates. The thickness of the thermal pad is crucial, be it too thick, the heat will cumulate and force the heat dissipated by the CPU to flow back.

- With precise calculation, the thermal pad we implemented is 3mm in height.

2.Copper & Aluminum Passive Heat Spreader

Heat spreader is known for improving the distribution of heat. Our tailor-made heat spreader is made with copper and aluminum. Four CNC designed semi-circle trail make sure that the heat pipes can be housed securely with the heat spreader.- The outer layer contains 96% of aluminum, the height is 23.5mm and it weighs 142g.

- The inner layer contains 99.9% of copper, the height is 23.5mm and it weighs 173g.

- Thermal paste is applied to give mechanical strength to the bond between heat sink and heat source. It eliminates air from the surface area and optimizes the heat transfer between the two contact surfaces.

- Absorb heat quicker than aluminum owing to higher heat conductivity efficiency. (Copper: 402; Aluminum: 266)

- Excellent performance in heat absorption

3.Copper Heat Pipe

Heat pipes are capable of transferring the heat from the source (evaporator) to the heat sink (condenser) over relatively long distances through the latent heat of vaporization of a working fluid. A typical heat pipe consists of a vessel that is first vacuumed, then charged with a working fluid and sealed hermetically. When the heat pipe is heated at one end, the working fluid evaporates from liquid to vapor (phase change). The vapor travels through the hollow core of the heat pipe to the other end at near sonic speed, where heat is being removed by the aluminum heat sinks at the sides.- To achieve maximum heat conduction and dissipation, four pure copper heat pipes are implemented.

- The diameter of each heat pipe is 8mm.

- Each pure copper heat pipe has the ability to dissipate 9w of heat.

- Each heat pipe contains 99% of copper.

Operating Temp.

Can withstand extended temperature from -40 to 85°C – board level

|

Operating Temp. |

|

|---|---|

|

UT : -40°C to 85°C |

|

|

System |

|

|

CPU Type |

Intel® 22nm Ivy Bridge Processor (Mobile) socket (rPGA988) Intel® Core™ i7-3610QE 2.3 GHz (6M Cache, 45W) Intel® Core™ i5-3610ME 2.7 GHz (3M Cache, 35W) Intel® Core™ i3-3120ME 2.4 GHz (3M Cache, 35W) |

|

Chipset |

Intel® QM77 Express Chipset (Intel® BD82QM77 PCH) |

|

Memory Type |

2 x 204-pin SO-DIMM support up to 16 GB dual channel DDR3 1333/1600, Non-ECC |

|

BIOS |

AMI® UEFI BIOS |

|

Watchdog |

1-255 sec. or 1-255 min. software programmable, can generate system reset |

|

Expansion Slot |

|

|

PCIe x1 |

1 for PCIe x1 from PCH |

|

PCI |

1 |

|

Mini PCIe |

1 |

|

Display |

|

|

Chipset |

Integrated GFX in Ivy Bridge processor |

|

Onboard VGA |

Yes, Max: SXGA 2048 x1536 @ 60 Hz |

|

LVDS |

Dual channel 24-bit LVDS, Max. 1920 x 1200 |

|

Onboard DVI-D |

Yes, (Max. resolution 1920 x 1200) |

|

Onboard HDMI |

Yes, (Max. resolution 1920 x 1200) |

|

Independent Display Capability |

VGA, LVDS, DVI-D, HDMI |

|

Audio |

|

|

Codec |

Realtek ALC892 High Definition Audio Codec *2W amplifier onboard |

|

Ethernet |

|

|

Chipset |

Intel® 82579LM & 82574IT GbE LAN (support 10/100/1000 Mbps) |

|

WOL |

Yes |

|

Boot from LAN |

Yes for PXE |

|

Rear I/O |

|

|

VGA |

1 x 15-pin VGA connector (female) |

|

DVI-D |

1 x 25-pin DVI-D connector (female) |

|

HDMI |

1 x 19-pin HDMI A Type connector (female) |

|

Ethernet |

2 x RJ45 |

|

COM |

1 x RS-232/422/485 with 5V/12V selectable |

|

|

Serial Signals RS232: DCD-, RXD, TXD, DTR-, GND, DSR-, RTS-, CTS- RS422: TX-, RX+, TX+, RX-, GND RS485: DATA-, DATA+, GND |

|

USB |

4 x USB 3.0 |

|

I/O Interface |

|

|

SATA |

2 x SATAIII (6 Gb/s) 2 x SATAII (3 Gb/s) Supports RAID 0,1,5,10 |

|

CF-SATA |

1 x for PCIe x1 |

|

USB |

4 x USB 2.0 ports by pin header |

|

COM |

5 x COM ports COM2~3 ports RS232 with 5V/12V selectable by pin header COM4 port supports RS232 by pin header COM5~6 ports RS232/422/485 by pin header" |

|

PS/2 |

1 x pin-header for PS/2 keyboard and mouse |

|

LVDS |

1 x 30-pin connector |

|

Fan |

1 x CPU fan 1 x System fan connector |

|

Parallel Port |

2 x 13-pin header |

|

DIO |

16-bit (8 in/8 out) |

|

OS support list |

|

|

Windows |

Windows XP x32、Windows XP x64、Windows 7 x32、Windows 7 x64 |

|

Linux |

Open SUSE 12.2、Ubuntu 12.04 |

|

Mechanical and Environment |

|

|

Form Factor |

Mini-ITX Industrial MB |

|

Power Type |

ATX |

|

Dimension |

170 x 170 mm (6.7" x 6.7" ) |

|

Operating Temp. |

UT : -40°C to 85°C |

|

Relative Humidity |

10% to 90%, non-condensing |

|

Certification |

|

|

Vibration test |

IEC 60068-2-64 Random Vibration test Frequency: 5Hz to 500Hz Acceleration: 3.0 g rms Test Axis: X, Y, Z axis Test Time: 30Min (Each axis) |

|

Shock test |

IEC 60068-2-27 Shock test Wave form: Half Sine Wave Acceleration: 100g Duration Time: 6ms |

|

MIL-STD-810G |

Temperature Shock: MIL-STD-810G Test Method 503.5 Temperature Shock Procedure I-C / Storage (Multi-cycle shocks from constant extreme temperature, Form 85°C to -40°C, Three cycle)

High Temperature: MIL-STD-810G Test Method 501.5 high Temp ( 96 hours @75°C non-operating + 72 hours @ 75°C operating )

Low Temperature: MIL-STD-810G Test Method 502.5 Low Temp ( 96 hours @ -40°C non-operating +72 hours @ -40°C operating ) |

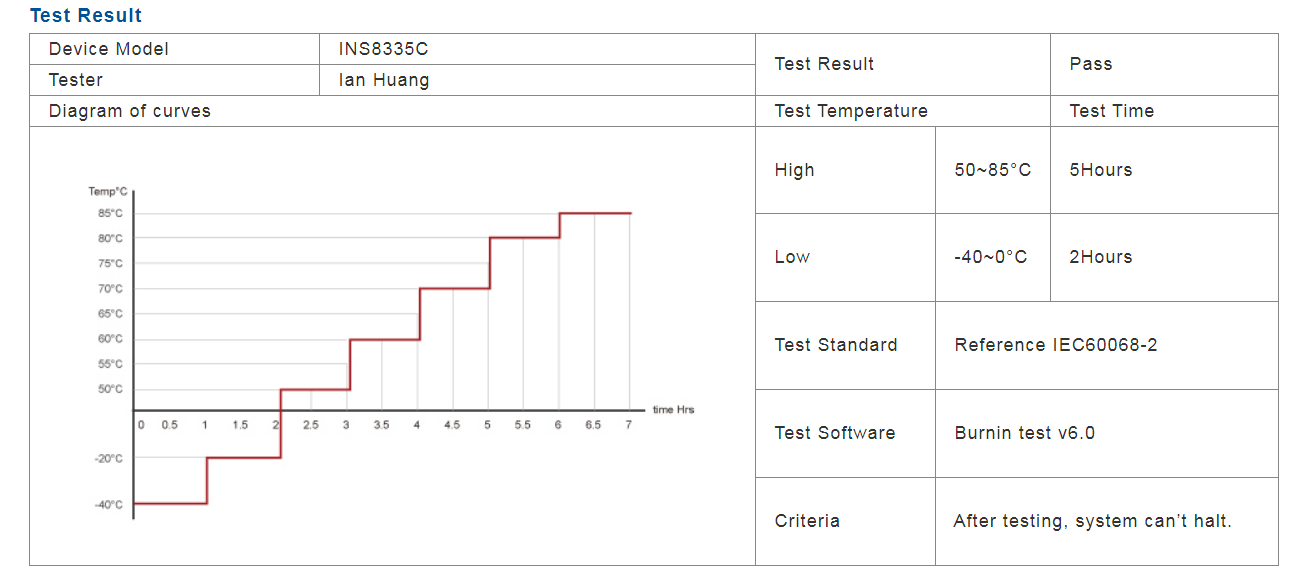

- Test Result

-

- Test Configuration

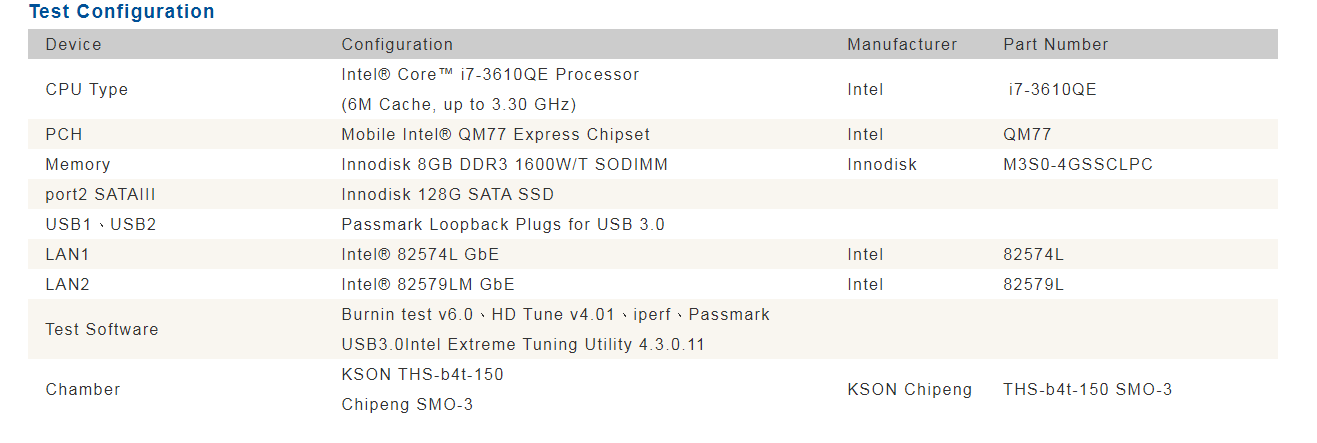

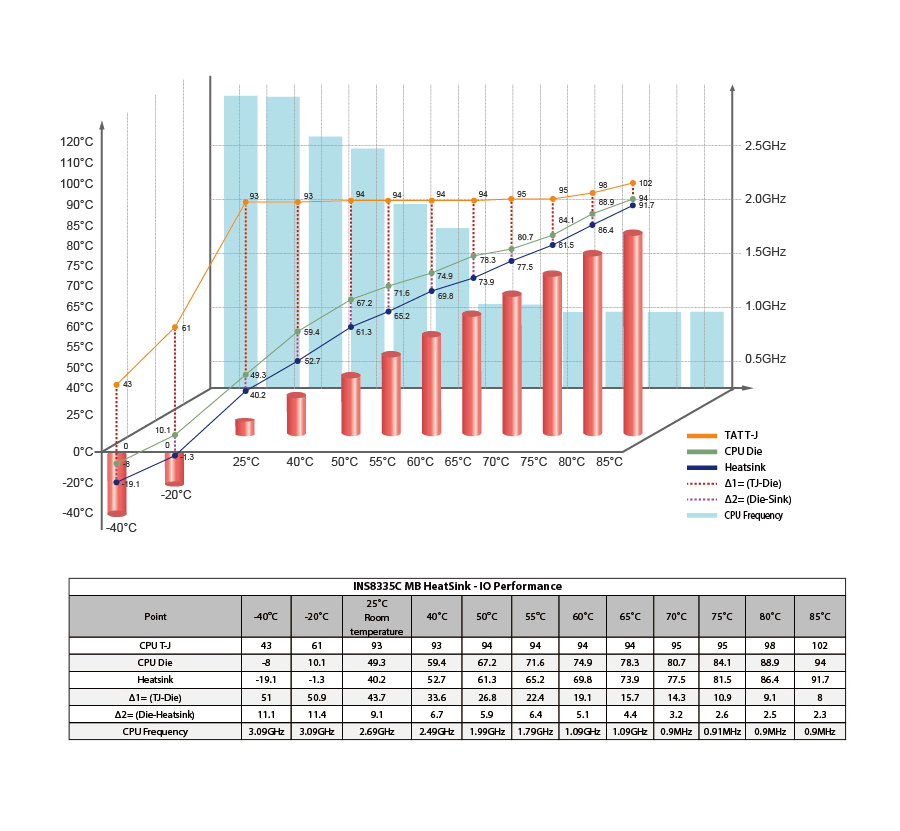

- Thermal Measurement

-

PERFECTRON provides real lab testing figures to show how CPU performance is with each tailor made thermal kits as important references and design guide for system engineers. For system integration, the crucial challenge is the operation performance under high temperature, thus PERFECTRON conducts long time experiments to make sure the superior testing result for all critical missions. By revealing temperature at processor T junction, processor die and heat sink, PERFECTRON is able to analyse the thermal solution we designed achieves maximum efficacy and observe CPU performance. The high temperature testing takes 5 hours which at each temperature point we burn in INS8335C for one hour, from +50 to +85°C.

- Related System — Core i Performance Fanless System PER535A

-

PER535A, a system made with convenience and strength in mind, is powered by Perfectron’s INS8335C high performance motherboard. PER535A can thrive at +70℃ without processor throttling and continually presents superior 2.3 GHz clock speed. Flexible expansion slot design features 1 x PCI & PCIe slot. 16 bit DIO can meet the needs of various different applications, such automation, energy exploration, medical and defence. Wide range DC in put design with ATX power supply from 9V to 24V can protect the system from sudden current fluctuation. For applications that require extreme resistance to shock and vibration, PER535A has passed IEC 60068-2-64& IEC 60068-2-27 vibration and shock tests. In an effort to permanently vanquish the malfunction due to crash and collision, PER335A is equipped with four rubber foot stands at the front side to prevent possible damages to I/O and power switch. With industrial grade handles assembled on two sides of the system, easy installation and utmost mobility are warranted.

- System main board: Mini-ITX SBC INS8335C

-

(1) Ever powerful Intel® Core i7 CPU

Rugged system demands an even stronger heart to pump it through all types of tough applications. Powered intel i7 CPU, both the computing power and the rugged ability are tightly secured.

(2) Industrial handles meet ergonomic design

By placing two industrial grade, extremely reliable handles on the side, the system can be installed and moved with ease.

(3) Comprehensive thermal design

Four rubber foot stands are installed in the front to protect front I/O and power switch from collision.

(4) Comprehensive thermal design

PER535A incorporates four pure copper heat pipes and a copper & aluminum passive heat spreader. On the two sides of the system are aluminum heat sinks to push the dissipation ability to a complete new level.

(5) Supreme resistance to shock & vibration (IEC compliant)The ability to withstand high level of shock and vibration is guaranteed through EC 60068-2-64& IEC 60068-2-27 vibration and shock tests.

- Supports Intel® 22nm Ivy Bridge Processor socket Type i7i5/i3

- 2 x DDR3 SO-DIMM up to 16 GB

- Supports 2.5" SATA HDD/SSD & CF-SATA socket

- 1 x VGA, 1 x DVI-D, 1 x HDMI

- Dual GbE LAN ports

- 2 x USB 3.0/ 4 x USB 2.0

- 5 x COM ports (2 x RS232/422/485, 3 x RS232)

- Supports wide range power input 9V~24V DC-in (By terminal block)

- Supports extended temp. -40 to +70°C

- Advanced cooling solution for better heat dissipation

-

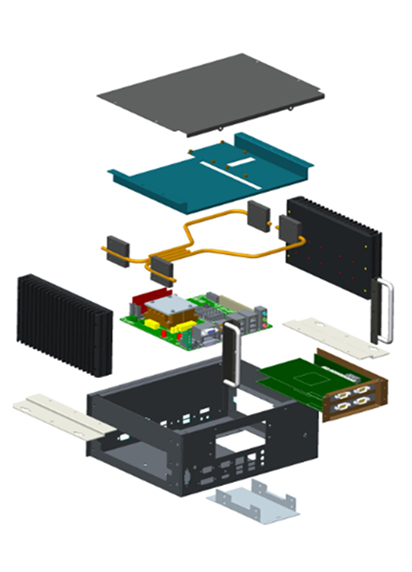

To meet the demands of customer’s extended temperature requirements, the whole thermal solution of INS8335C simultaneously embraces two heat transfer methods, heat conduction and heat convection. For heat conduction, the solution utilizes a copper heat spreader on the bottom layer which directly contact with the processor and chipset. Heat is then transferred to upper aluminum heat sink. Regarding to heat convection, the temperature differences caused by high and low fin design forms a mild airflow that could bring away heat efficiently. Fan can also be an auxiliary by placing an appropriate sized fan on top of the heat sink. Breakdown drawing is provided as below.

1. Thermal Pad

After countless experiments, PERFECTRON’s experienced engineer team has learned valuable lessons about the perfect thickness of thermal pad from failures.- Precise design of thermal pad: the gap between CPU die and heat sink should be less than 1mm.

2. Copper & Aluminum Heat Spreader

- The outer layer contains 96% of aluminum, the height is 23.5mm and it weighs 142g.

- The inner layer contains 99.9% of copper, the height is 23.5mm and it weighs 173g.

3. Pure Copper Heat Pipe

Heat pipe transfers heat from the heat sources to the heat sink over relatively long distance.Two-phase heat transfer involves the liquid-vapor phase change of a working fluid.- The longer ones are 365mm in length, 99.9% purity of copper.

- The shorter ones are 157mm in length, 99.9% purity of copper.

- High heat conductivity efficiency up to 5000.

4. Dual Sided Aluminum Heat Sink

- The heat sink each weighs 650g, and the height is 3.8cm

- The heat conducted by the heat sink will be dissipated by the aluminum heat sink placed on the two sides.

- Aluminum has higher efficiency in heat dissipation.